USA Security Systems

FLCC16145M

RICOH FL-CC1614-5M 2/3" 5MP 16mm Manual Iris Lens

RICOH FL-CC1614-5M 2/3" 5MP 16mm Manual Iris Lens

SKU:FL-CC1614-5M

Couldn't load pickup availability

*Please note tariff fee is included in price*

Optimize Your Machine Vision with the RICOH FL-CC1614-5M Lens

The RICOH FL-CC1614-5M (C31635KP) lens is a top-tier choice for professionals seeking precision imaging in industrial and machine vision applications. This high-performance manual iris lens is engineered to deliver unmatched clarity and detail, making it an essential component for those who demand accuracy in their inspection processes.

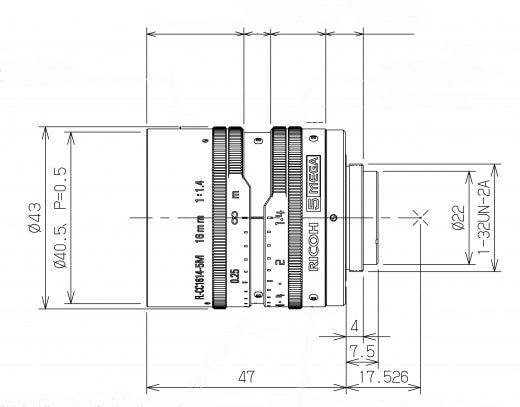

Featuring high resolution and contrast, the RICOH FL-CC1614-5M lens is designed with a compact Φ43 mm body, allowing it to fit seamlessly into various setups while maintaining exceptional image quality. One of its standout features is its minimal optical distortion, which ensures that every inspection is performed with the highest level of precision, from edge to edge.

The RICOH FL-CC1614-5M lens excels in a wide range of applications, such as visual inspection of printed circuit boards and sheet materials, verifying printed matter, and inspecting food and pharmaceuticals for defects. It's also ideal for detecting hairline cracks on sheet metals, checking for missing pixels on LCD monitors, and performing visual inspections on precision-machined items and containers.

For industries like electronics, automotive, and pharmaceuticals, the RICOH FL-CC1614-5M (C31635KP) lens is a game-changer, elevating your machine vision capabilities to ensure reliable, high-precision results.

| Format Size | 2/3" |

| Focal Length | 16 mm |

| Maximum aperture ratio | 1:1.4 |

| Iris Range | 1.4-16 |

| Mount | C |

| Horizontal Angle of View 1/3" Format | 17.1° |

| Horizontal Angle of View 1/2" Format | 22.7° |

| Horizontal Angle of View 1 1/8" Format | 25.4° |

| Horizontal Angle of View 2/3" Format | 30.8° |

| Min. Object Distance | 0.1 m |

| Back Focal Length | 11.5 mm |

| Filter Size | 40.5 P=0.5 mm |

| Dimensions | φ43×47 mm |

| Weight | 140 g |

| Comments | Focus & Iris lock screws |